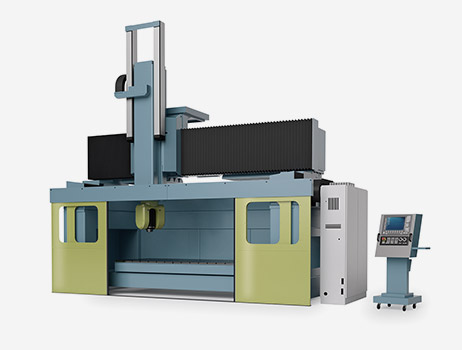

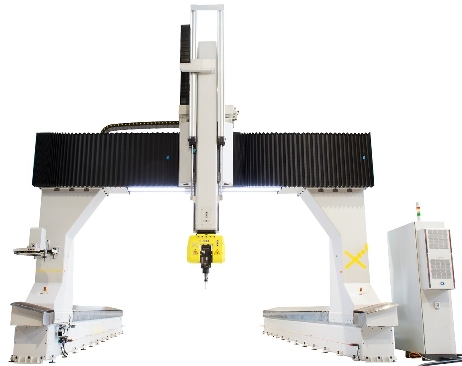

There are a wide range of Multiax machines for model and pattern makers, depending on the customer specific needs and the reference sector.

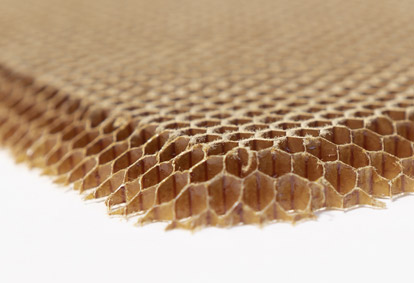

The typical materials are tooling boards, resins, fiberglass, wood. Beyond the machines, we can follow-up and suggest the most profitable machine configuration and also train the customer about all the aspects of making moulds related with the CNC machine (for example tools, program optimizations, etc), allowing the customer to make moulds with the machine independently right from the first day.

These CNC machines for model makers or prototype departments are often characterized by a series of features:

- Large work envelopes

- Special solutions to handle the big workpieces (trolleys, rails, etc.)

- Clamping and reference systems (on the floor, on tables or special)

- Touch probes to center and locate the work program

- 3D scanner for reverse engineering

- CAD/CAM, which allows to split the bigger parts into smaller sections to be machined individually, then joint together out of the machine

- Special tools for model makers

- Special application of PU/epoxy pastes with the CNC machine itself

- The active and passive safety: including enclosure of the machine, laser cells, closed circuit VDO cameras, efficient standard and tailored dust extraction systems

The use of a CNC Milling Machine for the construction of moulds have these main consequences:

- The production lead time of a new model will be much lower than required from the traditional process; this will allow modeler to produce more moulds and anticipate slower competitors with inferior technologies

- The dimensional tolerances are greatly reduced if compared with the deviations found in artifacts constructed manually

- The level of finish and surface brightness of the models obtained is adequate to produce a fiberglass mould of good quality that can still be improved by appropriate cycles

- The time needed for manual finishing of the model are reduced considerably, due to the surface finish made by the machine

- Reverse engineering, model adjustment or lengthening operations are greatly simplified, thanks to the use of ready-made CAM files that can be easily modified to the scope